The first step in building the slide is marking out the ice field. Starting about 25 feet from the shore line, a string is stretched 140 feet parallel to the bank. A marker is then pushed down along the string.

A right angle is then formed at a corner and a line is stretched 40 feet and marked. Measuring 20 feet, a line is marked down the middle of the field. Then the marker is used to make lines 22 inches wide the length of the field.

After marking out a channel towards shore, the ice is then ready for cutting. The ice field yields 1200 blocks of ice. When cut, the blocks are 15 1/2 inches wide, 44 inches long and the depth depends on the thickness of the ice. Usually the slide is built when the ice is 12 inches thick.

Before the cutting is started, the saw is set so that about an inch of ice is left to be cut by hand. This is done so the water doesn't get into the cuts and refreeze.

The channel is cut first. Then the field is cut lengthwise every 15 1/2 inches, starting in the middle and working out to the sides. Starting at one end, the field is ripped the width every 44 inches. After the field is cut, the ice is removed from the channel and the elevator is then put into place.

The next morning, a tractor is hooked up to the elevator by a belt. The ice blocks are then cut by hand saws and broken apart by the use of breaker bars.

After enough blocks are loose, they are floated into the channel to be pushed onto the elevator. With the help of ice poles, the blocks are floated down the field to the entrance of the channel. The last row is left intact of make it easier to move the ice blocks down the field.

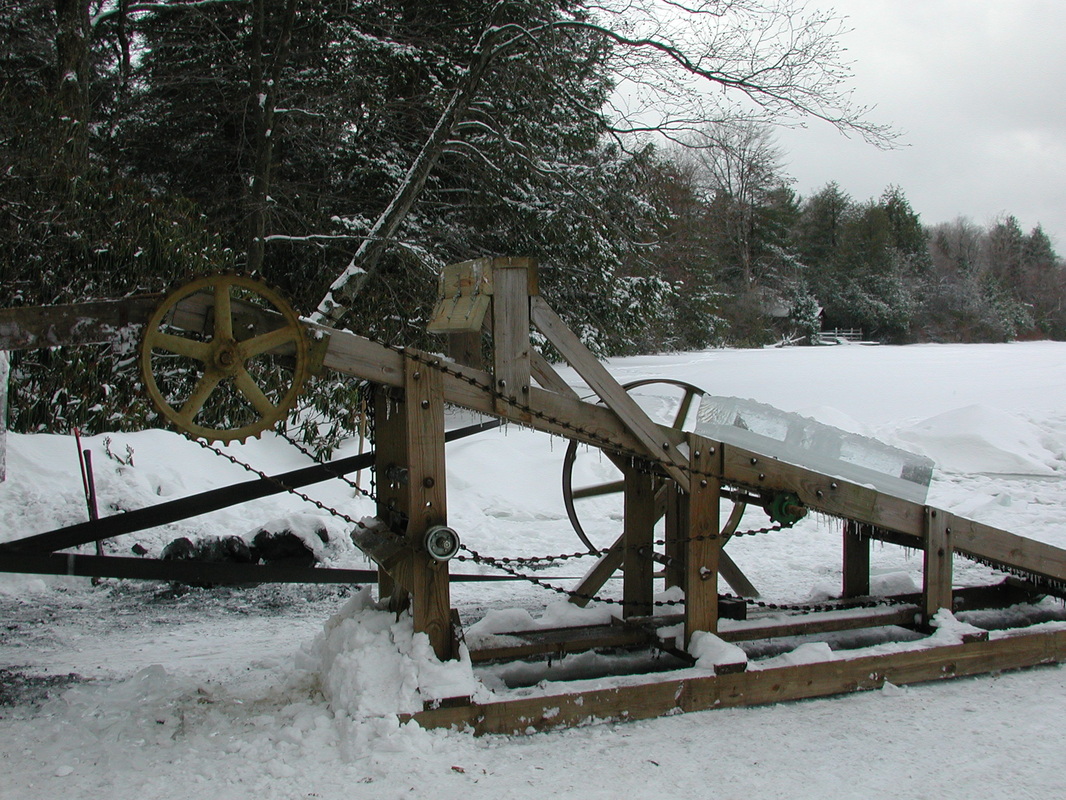

Using the ice poles, the ice blocks are then pushed onto the elevator. Wooden blocks connected to a chain lift the ice blocks up out of the water and onto the chute.

After the blocks reach the top of the elevator, they come down a chute to be loaded onto a pick-up truck. A trailer with an eight foot bed can hold up to six blocks of ice. Ice tongs are used by the men loading the trailer.

The ice is then hauled to the hill. A portable chute is placed on the truck, and the blocks are removed with ice tongs. Unloading the trucks is considered to be the hardest job. A single block weighs 256 pounds when the ice is 12 inches thick.

Starting about fifty feet out on the lake, the blocks are dragged from the trucks and are put into place heading towards the hill. This is done so that the ice doesn't slide down when placed up the hill. A string is used to keep the blocks as straight as possible.

The blocks are first laid up the hill. Boards are placed under the blocks to keep them level. Before some of the blocks are put into place, an ice shaver is used to knock off any rough edges. When all the blocks are laid on the hill, the workers return to the bottom and start laying the blocks across the lake.

The process of cutting blocks loose, loading the elevator and trucks, hauling, unloading, and placing the ice takes most of the day. After all the blocks are in place, snow is packed alongside the slide. If no snow is available, a fire truck is brought over and the slide is sprayed with water. The ice blocks are left to freeze in place overnight.

The next morning, the slide is grooved. Beginning at the top, a board is laid on one side of the ice, even with the edge. Then, pushing the groover by hand along the board, the groove is marked out. The groover is pushed the length of the slide twice, to insure that a deep enough mark is made.

Returning to the top, the marker is hooked up to a Jeep by cables. Behind the marker, the planer is connected by a chain. With several men on the planer and marker, the Jeep tows them the length of the slide. This is done until the slide has a groove two inches deep and 22 inches wide.

When the groove is deep enough the slide is given a cleaning. A snow plow is used first, and the remaining ice is blown out with a leaf blower. When the cleaning is done, the slide is tested for safety by volunteers. Once given the OK, the slide is ready to go.

By starting work on Friday, the slide is ready for the public by Sunday afternoon. It takes approximately 380 man hours to build the slide. An average of nine pick-up trucks are used, covering a total distance of 250 miles, and they carry approximately 1000 ice blocks, weighing a total of 120 tons.

A right angle is then formed at a corner and a line is stretched 40 feet and marked. Measuring 20 feet, a line is marked down the middle of the field. Then the marker is used to make lines 22 inches wide the length of the field.

After marking out a channel towards shore, the ice is then ready for cutting. The ice field yields 1200 blocks of ice. When cut, the blocks are 15 1/2 inches wide, 44 inches long and the depth depends on the thickness of the ice. Usually the slide is built when the ice is 12 inches thick.

Before the cutting is started, the saw is set so that about an inch of ice is left to be cut by hand. This is done so the water doesn't get into the cuts and refreeze.

The channel is cut first. Then the field is cut lengthwise every 15 1/2 inches, starting in the middle and working out to the sides. Starting at one end, the field is ripped the width every 44 inches. After the field is cut, the ice is removed from the channel and the elevator is then put into place.

The next morning, a tractor is hooked up to the elevator by a belt. The ice blocks are then cut by hand saws and broken apart by the use of breaker bars.

After enough blocks are loose, they are floated into the channel to be pushed onto the elevator. With the help of ice poles, the blocks are floated down the field to the entrance of the channel. The last row is left intact of make it easier to move the ice blocks down the field.

Using the ice poles, the ice blocks are then pushed onto the elevator. Wooden blocks connected to a chain lift the ice blocks up out of the water and onto the chute.

After the blocks reach the top of the elevator, they come down a chute to be loaded onto a pick-up truck. A trailer with an eight foot bed can hold up to six blocks of ice. Ice tongs are used by the men loading the trailer.

The ice is then hauled to the hill. A portable chute is placed on the truck, and the blocks are removed with ice tongs. Unloading the trucks is considered to be the hardest job. A single block weighs 256 pounds when the ice is 12 inches thick.

Starting about fifty feet out on the lake, the blocks are dragged from the trucks and are put into place heading towards the hill. This is done so that the ice doesn't slide down when placed up the hill. A string is used to keep the blocks as straight as possible.

The blocks are first laid up the hill. Boards are placed under the blocks to keep them level. Before some of the blocks are put into place, an ice shaver is used to knock off any rough edges. When all the blocks are laid on the hill, the workers return to the bottom and start laying the blocks across the lake.

The process of cutting blocks loose, loading the elevator and trucks, hauling, unloading, and placing the ice takes most of the day. After all the blocks are in place, snow is packed alongside the slide. If no snow is available, a fire truck is brought over and the slide is sprayed with water. The ice blocks are left to freeze in place overnight.

The next morning, the slide is grooved. Beginning at the top, a board is laid on one side of the ice, even with the edge. Then, pushing the groover by hand along the board, the groove is marked out. The groover is pushed the length of the slide twice, to insure that a deep enough mark is made.

Returning to the top, the marker is hooked up to a Jeep by cables. Behind the marker, the planer is connected by a chain. With several men on the planer and marker, the Jeep tows them the length of the slide. This is done until the slide has a groove two inches deep and 22 inches wide.

When the groove is deep enough the slide is given a cleaning. A snow plow is used first, and the remaining ice is blown out with a leaf blower. When the cleaning is done, the slide is tested for safety by volunteers. Once given the OK, the slide is ready to go.

By starting work on Friday, the slide is ready for the public by Sunday afternoon. It takes approximately 380 man hours to build the slide. An average of nine pick-up trucks are used, covering a total distance of 250 miles, and they carry approximately 1000 ice blocks, weighing a total of 120 tons.